Blog

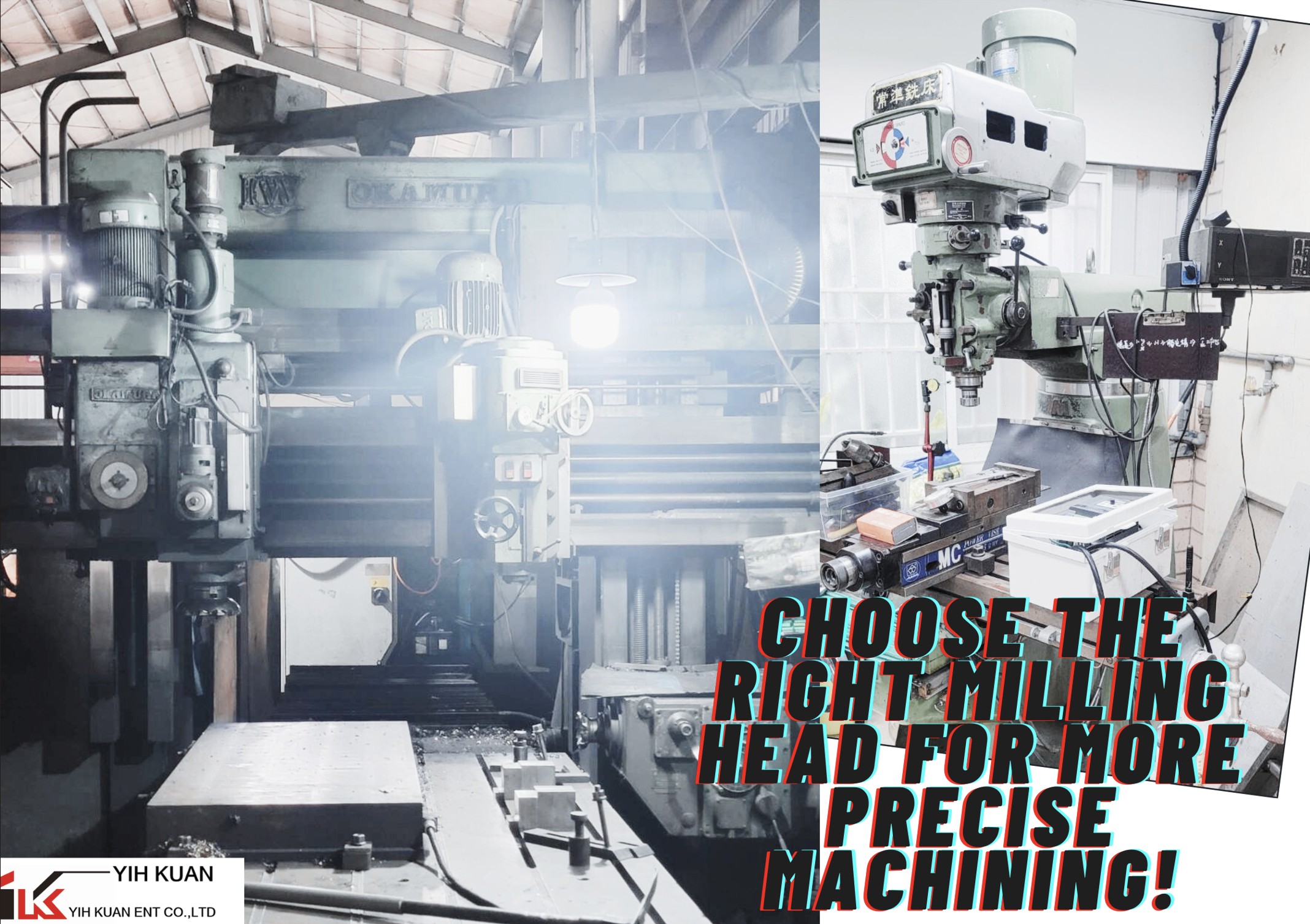

Choosing the Right Milling Head: Unlocking Your Machine’s Full Potential

2025.03.18

Understanding the Importance of Milling Head Selection

In the world of precision machining, selecting the right milling head is crucial for achieving optimal performance, efficiency, and machining accuracy. However, many users simply adopt the standard milling head provided by the machine manufacturer without considering whether it truly meets their specific machining requirements. This often limits the machine’s full capabilities, preventing businesses from maximizing their production potential.

Recently, Yih Kuan (IK Milling Head) received an inquiry from a customer who owns a Japanese milling machine and wanted to replace its milling head. The customer asked:

"Is it possible to change the milling head on my machine?"

After reviewing the provided photo, Yih Kuan responded with expert guidance:

"Yes, it’s definitely possible! However, it is important to confirm certain dimensions, technical requirements, and machining characteristics to ensure a proper fit and seamless integration."

This inquiry highlights a common industry challenge—many manufacturers may not realize that milling head replacement and customization can dramatically enhance their machining capabilities, improve precision, and expand production flexibility.

The Role of Milling Heads in Machining Performance

A milling head is the core component of a milling machine, responsible for performing precise cutting, drilling, and shaping operations. It directly impacts factors such as:

- Machining accuracy – A high-quality milling head ensures precision in every cut.

- Production efficiency – The right milling head can reduce machining time and improve workflow.

- Versatility – Different milling heads offer unique capabilities suited for various machining applications.

- Longevity – Upgrading to a well-designed, high-rigidity milling head extends the lifespan of the entire machine.

By choosing the correct milling head, manufacturers can unlock the true potential of their equipment, enabling them to handle more complex machining tasks and increase overall productivity.

Comprehensive Milling Head Solutions by Yih Kuan

With decades of expertise in milling head manufacturing, Yih Kuan (IK Milling Head) specializes in producing a wide range of high-performance milling heads, including:

- CNC Gantry Gear Heads – Designed for high-torque, heavy-duty machining applications, ensuring precise and stable performance.

- Machining Center Gear Heads – Engineered for high-speed CNC milling centers, optimizing productivity and machining efficiency.

- Plano Milling Heads – Perfect for large-scale surface milling, providing rigid support and accuracy for various industries.

- Turret Milling Heads – Ideal for general machining, offering flexibility for manual and CNC-controlled milling operations.

- Angular Heads – Expand machining capabilities by allowing multi-directional cutting without repositioning the workpiece.

Beyond standard models, Yih Kuan also offers customized milling head solutions, tailoring configurations to match unique customer requirements. This ensures seamless integration with existing milling machines, enhancing machining efficiency and versatility.

Key Considerations for Milling Head Replacement

Before upgrading or replacing a milling head, it is essential to assess key factors such as:

- Spindle interface compatibility – Ensuring the new milling head matches the machine’s spindle mounting specifications.

- Required machining capabilities – Considering factors like cutting speed, torque, and rigidity needed for specific applications.

- Machine capacity and structural support – Verifying whether the existing machine structure can handle a more powerful milling head.

- Automation and CNC integration – Determining if the new milling head is compatible with CNC control systems for precision automation.

Proper evaluation of these aspects will ensure a smooth transition and maximize the performance benefits of a new milling head.

Unlock Your Machine’s Full Potential with Yih Kuan (IK Milling Head)

At Yih Kuan, we understand that every machining requirement is unique. Whether you need a high-precision CNC milling head, a durable plano milling head, or a specialized angular head, our expert team can help you find or customize the perfect solution.

- Why settle for standard when you can optimize?

- Enhance your machining capabilities with a tailored milling head upgrade!

For professional milling head solutions, contact Yih Kuan (IK Milling Head) today and explore how our expertise can elevate your machining performance to new levels