Blog

How to choose the correct gantry milling head?

2022.08.10

There are two types of gantry milling machine, CNC computer type and non-NC computer type (traditional manual type). It is a milling machine with a portal frame and a horizontal long bed. Gantry milling machines are suitable for machining flat and inclined surfaces of large workpieces in batch and mass production. CNC gantry milling machines can also process space curved surfaces and some special parts.

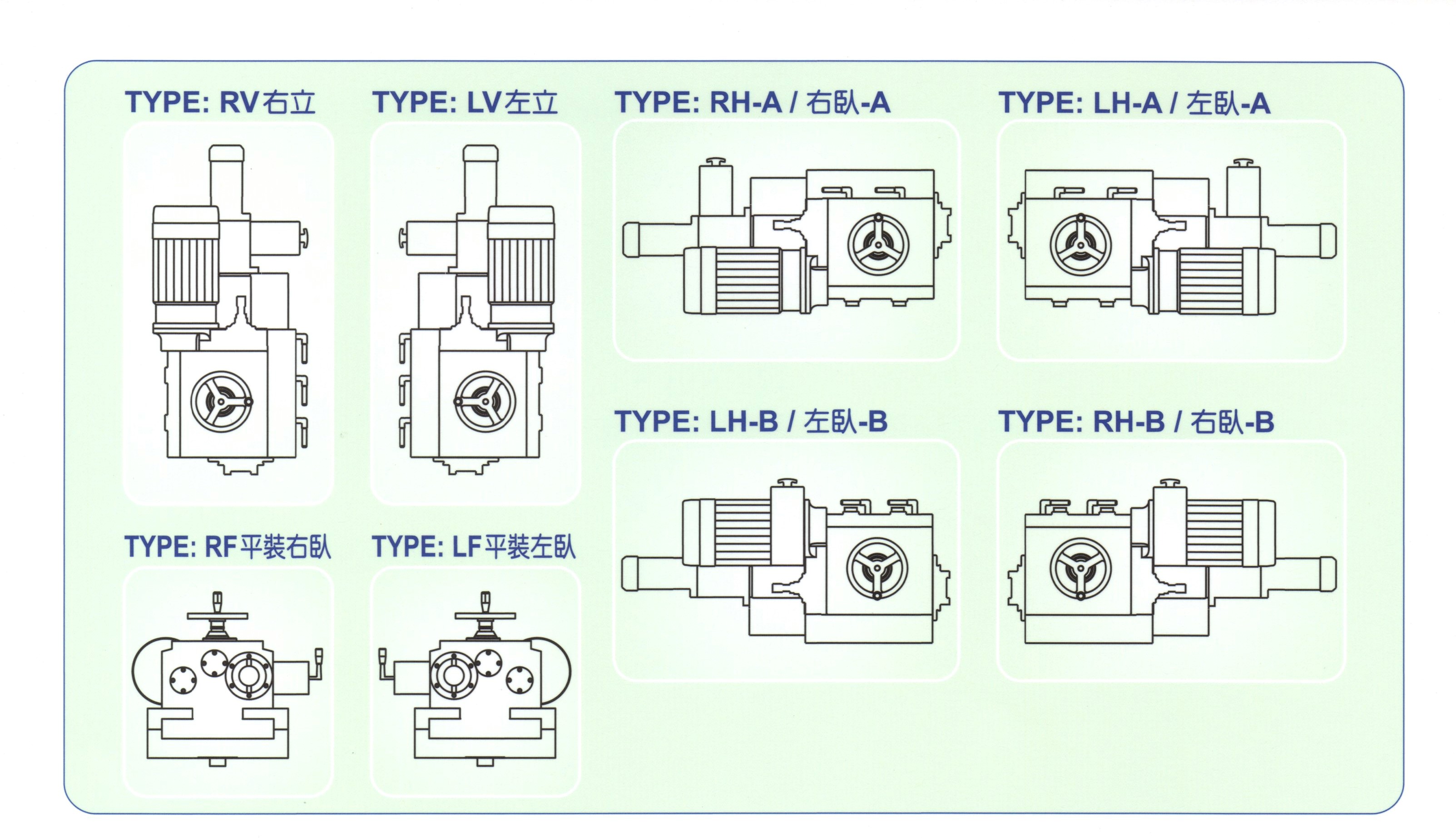

In recent years, the usage habits and processing conditions of gantry milling machines are different, so gantry milling heads have also successively introduced milling heads in different directions for use in machine tools (vertical/horizontal milling heads), and also widely load angle heads/horizontal milling heads. So that the processing range of the gantry milling machine is wider to meet the more difficult processing requirements.

Mention traditional gantry milling head, how to choose the correct one to install on a gantry machine?

There are two options:

- Machine body, according to the connection plate on the gantry milling machine, confirm which type of milling head the connection hole matches.

- Application, according to the user's processing conditions.

(Such as: processing material, processing efficiency, cutting amount...etc.)

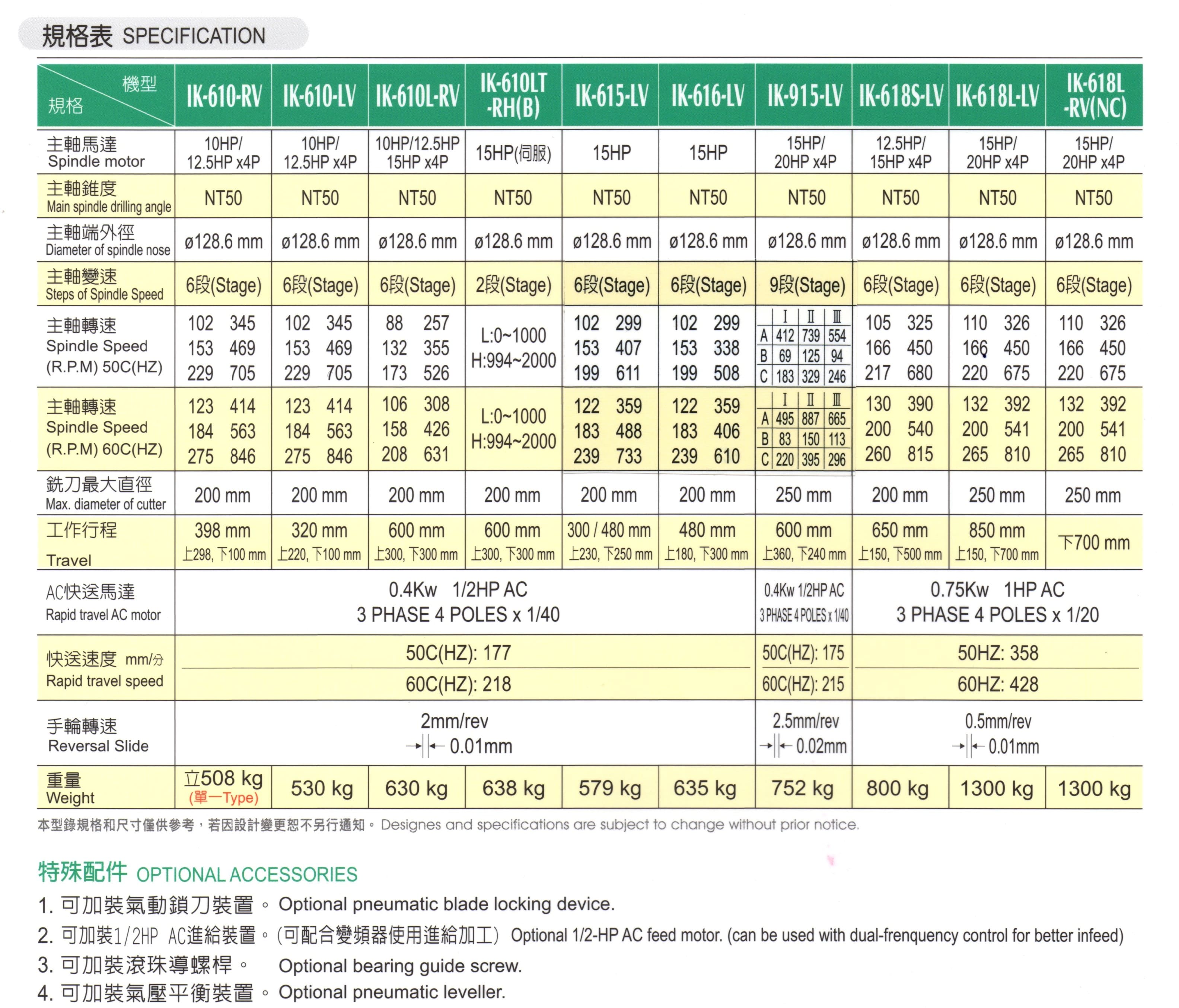

Traditional gantry milling heads can generally be distinguished from the size of the motor, gear speed, processing travel and the connection hole position behind the milling head:

-Size of motor: 10HP/12.5HP/15HP/20HP/other

-Gear speed: 2 stages/6 stages/9 stages/other

- Processing travel: 320mm~700mm/other

Besides, it can also as a match basis through the connection holes on the back of the milling head (if the user needs to modify or replace the milling head).

In necessary, you need to customize a special gantry milling head to match the special body.

(Such as: super large gantry milling machine, gantry milling machine with special processing conditions.)