Blog

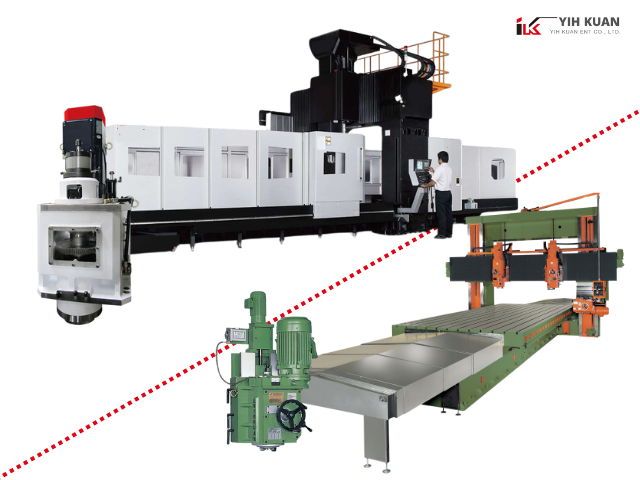

Navigating the Choice: CNC Gantry Milling Machines vs. Traditional Gantry Milling Machines

2024.08.01

Introduction

In the realm of industrial manufacturing, gantry milling machines stand out for their robust capabilities in handling large and intricate workpieces. The decision between CNC and traditional gantry milling machines can impact production efficiency, precision, and operational cost. This article delves into the distinctions between these two types of machines, discusses the critical role of milling heads manufactured by Yih Kuan, and outlines best practices for their maintenance and replacement.

Understanding Gantry Milling Machines

Gantry milling machines feature a bridge-like structure that spans over the workpiece, allowing the milling head to move along the X, Y, and Z axes. This setup provides stability and support for machining large parts, making it ideal for heavy-duty industries.

CNC Gantry Milling Machines

- Technology: Utilizes computer numerical control to automate and precisely control all movements, ensuring high accuracy and repeatability.

- Advantages: Offers significant improvements in speed, efficiency, and the ability to produce complex geometries with minimal human intervention.

- Industries Served: Particularly favored in aerospace, automotive, and precision engineering industries where complex, repetitive tasks are common.

Traditional Gantry Milling Machines

- Technology: Operates based on manual adjustments and settings, which requires skilled operators to achieve the desired accuracy.

- Advantages: Cost-effective for simpler, less intricate tasks. It allows for direct control and adjustments by the operator, often preferred in custom or specialized projects.

- Industries Served: Used widely in shipbuilding, heavy equipment fabrication, and industries where large scale, less complex machining is required.

The Role of Milling Heads in Gantry Milling Machines

Milling heads play a pivotal role in the functionality of both CNC and traditional gantry milling machines. Yih Kuan designs and manufactures high-quality milling heads suitable for a diverse range of machining needs, ensuring that whether your operations require precision CNC applications or robust traditional machining, the right tool is available.

Importance of Milling Heads: The performance of a gantry milling machine largely depends on the quality and condition of its milling head. These components are crucial for efficiently cutting, carving, and shaping metal and other materials. The precision and durability of a milling head significantly influence the machining accuracy and the quality of the final product.

Maintenance and Replacement Indicators:

Maintenance: To ensure consistent performance and prolong the life of milling heads, regular maintenance is crucial. This includes routine lubrication, cleaning, and inspection for wear and tear. Keeping milling heads in good condition helps in maintaining the precision and efficiency of the machine.

Signs that Indicate Maintenance or Replacement:

- Decreased Performance and Efficiency: If the milling machine starts taking longer to complete tasks or struggles with operations that it used to handle easily, it might be time to check the milling head.

- Poor Surface Finish: A deterioration in the surface finish of machined parts, such as roughness or unexpected marks, can indicate that the milling head is worn out or damaged.

- Increased Vibration or Noise: An increase in noise or vibration during operation can suggest that the milling head's components may be worn or misaligned.

- Visible Wear or Damage: Any visible cracks, chips, or wear on the milling head are clear indicators that maintenance or replacement is necessary.

- Excessive Heat Generation: Overheating during operations can be a sign of a dull or improperly lubricated milling head.

- Difficulty in Tool Insertion or Removal: Problems with changing tools can indicate issues with the spindle or tool holder components of the milling head.

Choosing Between CNC and Traditional Machines

When deciding between a CNC and a traditional gantry milling machine, manufacturers should consider:

- Production Requirements: Evaluate the complexity of the parts being produced and the precision required.

- Volume: High-volume manufacturers may find the automation of CNC machines more beneficial, while traditional machines may be more cost-effective for lower volumes.

- Cost: CNC machines represent a higher initial investment but offer savings through faster production times and reduced labor costs over time.

Conclusion

The choice between CNC and traditional gantry milling machines depends largely on specific production needs, cost considerations, and desired outcomes. With Yih Kuan’s high-quality milling heads, manufacturers can enhance both types of machines, ensuring efficient and precise machining operations. Yih Kuan remains committed to supporting manufacturers in choosing the right equipment and maintaining it to the highest standards. For further information on selecting and caring for milling heads suitable for your gantry milling machines, please contact Yih Kuan. We are dedicated to helping you optimize your manufacturing processes and achieve superior results.