Blog

Maximizing Turret Milling Machine Capabilities with Advanced Milling Heads

2024.09.05

Introduction

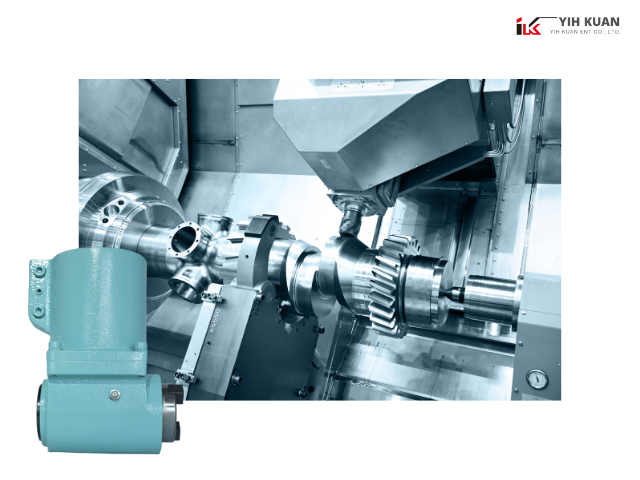

Turret milling machines are foundational in many manufacturing settings, valued for their versatility and precision in detailed machining tasks. To further enhance their capabilities, Yih Kuan Enterprise Co., Ltd. introduces innovative milling heads, including horizontal and angle heads, designed to extend the functionality and efficiency of turret milling machines. For more insights on the importance of angle heads in turret milling, explore our detailed discussion here.

Understanding Turret Milling Machines

Turret milling machines are distinguished by their stationary spindle and the table that moves both perpendicular and parallel to the spindle axis to accomplish cutting tasks. This configuration allows for flexible machining operations, making the turret mill ideal for smaller manufacturing jobs involving intricate detailing or prototyping.

Key Advantages of Turret Milling Machines

- Versatility: They can perform a range of functions including drilling, cutting, and shaping across multiple axes.

- Precision: With advanced controls, they can achieve precise cuts with high accuracy.

- Ease of Use: Turret mills are generally more user-friendly and easier to set up compared to larger milling machines.

Integrating Advanced

Milling Heads Yih Kuan's new line of milling heads, specifically designed for turret milling machines, expands these capabilities:

- Horizontal Milling Heads: These enhance the ability to efficiently remove material over large surface areas, making them ideal for jobs requiring extensive milling.

- Angle Heads: Allow machining at various angles, significantly reducing the setup time and enabling complex geometries to be machined more easily.

Applications and Benefits

- Enhanced Machining Options: With the integration of these advanced milling heads, manufacturers can take on more complex projects, such as multi-angle cuts and extensive material removal, without the need for multiple setups or different machines.

- Increased Productivity: The ability to perform diverse tasks with a single setup reduces downtime and increases throughput.

- Cost Efficiency: By enhancing the capabilities of the turret milling machine, manufacturers can avoid the high costs associated with purchasing specialized machinery.

Maintenance and Replacement

Maintaining these advanced milling heads involves regular checks for alignment, wear, and proper lubrication. Signs that indicate a need for maintenance or replacement include unusual noise, decreased efficiency, and poor finish quality. Timely attention to these signs ensures continuous high performance and extends the lifespan of both the machine and the head.

Conclusion

The addition of Yih Kuan’s advanced milling heads to your turret milling operations can transform your production capabilities, making it possible to tackle more complex and varied tasks efficiently. For manufacturers looking to enhance their machining processes and explore new manufacturing possibilities, Yih Kuan offers the tools and expertise to make it happen.

Call to Action

Explore the full potential of your turret milling machines with Yih Kuan’s innovative milling heads. Contact us today to learn more about how our products can enhance your manufacturing efficiency and productivity.