Blog

The Value of Traditional Gantry Milling Machines and Yih Kuan's Solutions

2025.02.14

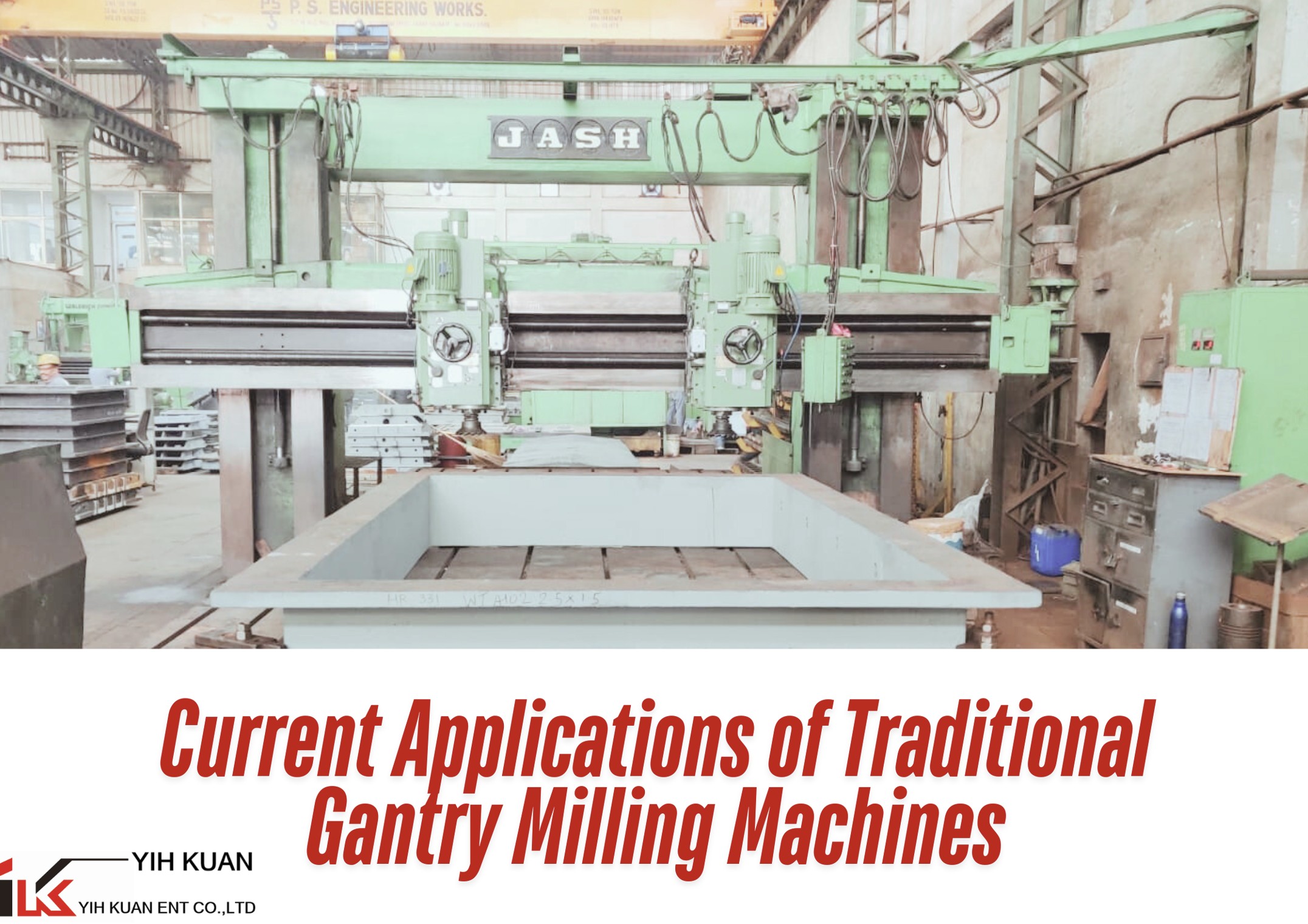

With the widespread adoption of modern CNC gantry milling machines, traditional gantry milling machines have gradually declined. However, they continue to play an irreplaceable role in specific markets and applications. Yih Kuan's perspective on traditional gantry milling machines is as follows:

1. Cost-Effective, Suitable for Small and Medium Enterprises

While CNC gantry milling machines offer high automation, they are expensive, including procurement costs, maintenance expenses, and operator training costs. In contrast, traditional gantry milling machines require lower initial investment, making them an economical choice for small and medium enterprises or factories with lower production volumes. Additionally, traditional gantry milling machines can now be retrofitted with NC semi-automatic functions, transforming manual milling into automatic feeding and significantly improving overall machining efficiency.

2. Highly Flexible, Suitable for Specific Machining Needs

Traditional gantry milling machines can adapt flexibly to different machining requirements without the need for complex programming. This is highly advantageous for single-piece or small-batch machining, especially in maintenance, mold manufacturing, and fixture production, where traditional gantry milling machines still play a crucial role.

3. Operator Experience-Dependent Machining Precision

The precision and efficiency of traditional gantry milling machines largely depend on the skill level of the operator. An experienced technician can achieve high-precision machining with traditional equipment. However, compared to CNC machines, traditional ones are less suitable for standardized mass production. Some skilled engineers even modify existing equipment to expand machining capabilities or develop unique processing methods.

4. Suitable for Maintenance and Heavy Industrial Machining

Traditional gantry milling machines remain widely used in large equipment maintenance, shipbuilding, steel, and energy industries. These sectors often handle large workpieces that are difficult to standardize and require manual adjustments to accommodate different machining scenarios, ensuring continued market demand for traditional equipment.

5. Upgradeable and Modifiable for Extended Lifespan

With advances in digital technology, traditional gantry milling machines can be upgraded by replacing milling heads, adding digital readout systems (optical scales), and upgrading servo drives to enhance machining precision and efficiency. This allows older equipment to continue providing value in modern factories.

Yih Kuan's Gantry Milling Head Solutions

Yih Kuan specializes in manufacturing high-performance milling heads suitable for various gantry milling machines, whether traditional models or NC/semi-automatic machines. We provide milling head solutions that enhance machining performance and production efficiency.

Features of Yih Kuan Gantry Milling Heads:

-

High-Rigidity Design: Ensures machining stability, suitable for heavy cutting and high-precision applications.

-

Diverse Models: Offers standard, high-speed, and heavy-duty milling heads to meet various machining needs.

-

Precision Gear Transmission: Provides smooth and high-performance power output for prolonged machining operations.

-

Automatic Feeding Compatibility: Some models support NC or semi-automatic control to enhance machining efficiency.

-

Customized Solutions: We provide milling heads with specific clamping methods and speed configurations tailored to customer needs.

Applications

Yih Kuan's gantry milling heads are suitable for various traditional and modern gantry milling machines, making them ideal for mold manufacturing, aerospace component production, energy equipment machining, and large-scale machinery maintenance. By upgrading with high-performance milling heads, customers can significantly enhance the machining capabilities and efficiency of their existing equipment without replacing entire machines.

Conclusion

Although CNC gantry milling machines have become mainstream, traditional gantry milling machines still play a role in specific applications. Their cost-effectiveness, flexibility, and maintainability make them suitable for maintenance machining, single-piece production, and certain heavy industrial applications. For businesses, choosing the right machining equipment or upgrading traditional machines to improve efficiency remains a valuable option.

Yih Kuan is committed to providing high-quality gantry milling head solutions, helping customers maximize equipment value and enhance machining performance. For inquiries regarding technical details and customized solutions, please contact us!