Blog

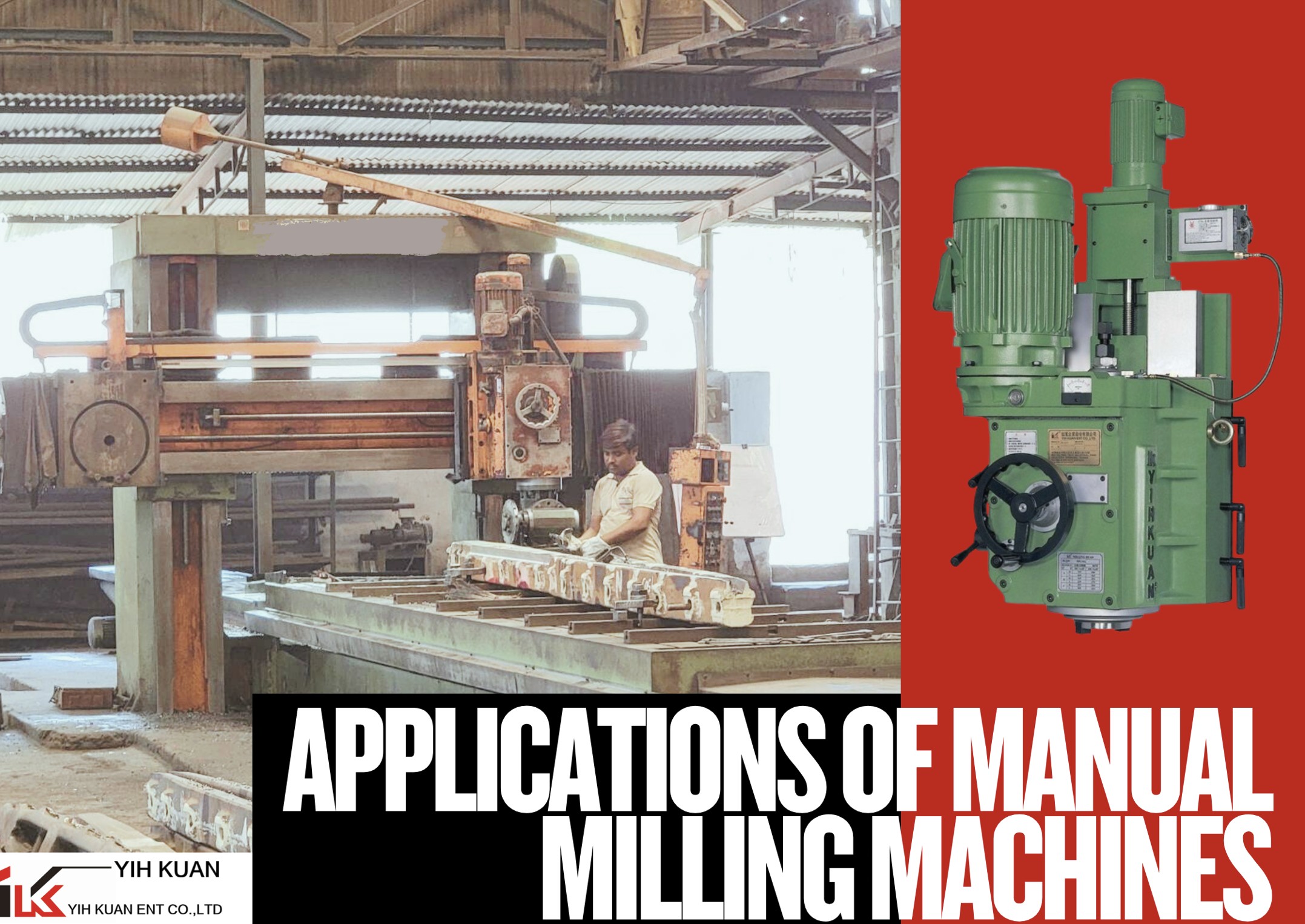

Applications of Manual Milling Machines

2025.02.12

Manual milling machines still have unique advantages in the machine tool industry, particularly in the following applications:

1. Single-piece and Small-batch Production

Manual milling machines do not require complex programming or automation setup, making them ideal for producing small quantities of diverse parts, such as repair components, prototypes, and experimental parts.

2. Mold Manufacturing and Modification

For mold repair and modification, manual milling machines allow for quick material removal to accommodate urgent adjustments, such as edge refinements or groove machining.

3. Education and Training

Technical education and academic institutions frequently use manual milling machines as entry-level equipment to teach students fundamental concepts such as cutting forces, feed rates, and machining precision.

4. Equipment Maintenance and Adjustment Machining

In mechanical equipment maintenance, many parts require modifications or precise fitting. Manual milling machines provide a flexible and quick solution for these tasks.

5. Special Angle and High-flexibility Machining

When machining complex shapes or special angles that are difficult for CNC machines to handle, manual milling machines allow skilled operators to make precise adjustments to achieve the required accuracy.

The Key Role of Milling Heads

The milling head is the core component of a milling machine, determining its cutting capability, machining accuracy, and application range. Its primary functions include:

1. Providing Cutting Power and Speed Adjustment

The spindle speed, torque, and drive mechanism of the milling head define its machining capabilities, whether for high-speed precision machining or heavy-duty cutting.

2. Expanding Machining Range and Flexibility

Different types of milling heads, such as angle heads and universal milling heads, enhance the machine’s flexibility, allowing it to machine various angles, curved surfaces, or hard-to-reach areas.

3. Affecting Machining Precision and Rigidity

The rigidity, bearing configuration, and spindle design of the milling head influence the machine’s stability and precision, especially in heavy-duty cutting operations.

4. Determining Compatible Tooling Options

The spindle specifications (e.g., BT, NT, HSK) define the range of compatible tools, impacting machining efficiency and the types of materials that can be processed.

Can Replacing the Milling Head Significantly Improve Performance?

The answer is "Yes, but it depends on the situation."

If the machine structure and rigidity are sufficient, simply upgrading the milling head—such as replacing it with a high-speed spindle, reinforced milling head, or angle head—can significantly enhance machining efficiency and accuracy.

However, if the machine base lacks rigidity or if the guideways are worn, even a high-performance milling head may not perform optimally and could lead to machine vibration or increased machining errors.

For numerical control (NC) applications, replacing only the milling head while keeping the machine manually operated will have limited efficiency improvements. In such cases, upgrading to an NC or CNC-controlled milling machine may be necessary.

Yih Kuan (IK Milling Head) specializes in milling head design and manufacturing. Since 1977, we have been producing everything from milling head components to complete milling head assemblies. If you have any inquiries about milling heads, we are more than happy to discuss and help configure the best milling head solution for your machine.

(CNC milling spindle gearbox / Gantry (Plano) milling heads / Turret milling heads / Milling angle heads... etc.)

Conclusion

Manual milling machines remain ideal for single-piece, small-batch, repair, and special machining applications, offering advantages in cost and flexibility.

The milling head determines machining capability, flexibility, and precision, and upgrading it can enhance performance, but the results depend on the overall machine condition.

If the machine structure is solid, replacing the milling head can significantly improve machining performance. However, if rigidity is insufficient or guideways have lost precision, a full machine upgrade may be necessary.

If you have specific machine models or machining requirements, feel free to provide more details, and Yih Kuan (IK Milling Head) will help assess the best milling head upgrade solution for you!